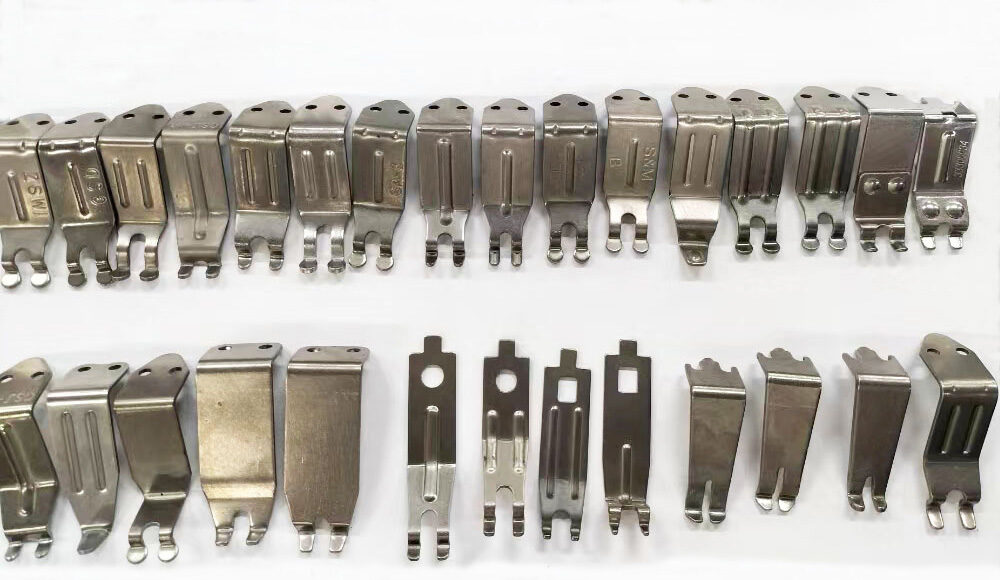

In wave soldering, every detail matters — especially the components responsible for holding the PCB securely during the process. One of the often-overlooked but critical parts is the Titanium Finger. If you’re still using standard metal claws, this small upgrade could bring noticeable improvements to your production line.

At SMTSTOCK, we supply high-quality Titanium Fingers that are already being used by many EMS factories and wave soldering lines around the world. Whether you’re replacing worn-out mechanical parts or looking for a performance upgrade, these are worth considering.

Why More Manufacturers Are Switching to Titanium Fingers

✔ Heat-Resistant and Durable

Titanium holds up under high soldering temperatures without deforming or losing strength — a key advantage over traditional stainless steel.

✔ Corrosion-Resistant, Less Maintenance

Thanks to titanium’s resistance to flux and chemical corrosion, there’s less cleaning, fewer replacements, and lower long-term costs.

✔ Smooth Surface, Easy to Clean

A clean claw means fewer defects and better production yield. Our fingers are polished for smoother operation and less solder build-up.

✔ Precision Machined, Ready to Install

Each unit is carefully manufactured to fit common wave soldering conveyors. No modification needed — just install and run.

Stock Models Available – Fast Delivery

We offer multiple standard sizes with inventory ready for dispatch. If you need custom dimensions or drawings, our team can assist with quick turnaround times.

Common Applications

-

Wave soldering lines (single or dual wave)

-

PCB conveyors

-

Fixture holding systems

-

Compatible with most international brands

Contact Us

If you’re looking to upgrade your current setup or need replacements for your current mechanical claws, feel free to contact us.

📧 Email: sales@smtstock.com

🌐 Website: https://smtstock.com/product-category/titanium-fingers/

We’re here to help you keep your production smooth, stable, and efficient.