Features

High Printing Precision

Achieves ±0.025mm printing accuracy and ±0.01mm repeatability, ensuring high-quality results for fine-pitch components.Advanced Dual Print Head System

Equipped with two independent motorized printheads for smooth, stable, and accurate squeegee movement.Flexible PCB Handling

Supports a wide range of PCB sizes (80×50mm to 400×340mm) and thicknesses (0.4~15mm), ideal for various SMT production needs.Smart Cleaning System

Programmable cleaning with dry, wet, and vacuum modes ensures stencil cleanliness and reduces downtime.Fast Setup and Changeover

Less than 5 minutes required to change product setup, increasing production efficiency for multiple batch orders.Closed-Loop Squeegee Pressure Control

Provides precise and visible pressure settings with software control, improving printing consistency and reducing defects.User-Friendly PC Control Interface

PC-based control with intuitive software enables easy parameter adjustment, monitoring, and diagnostics.Versatile Clamping & Support System

Multiple clamping and board support options (magnetic pin, vacuum nozzle, flexible pins) to suit different PCB shapes and thicknesses.

Technical Parameters

| Item | GKG GSE |

|---|---|

| Repeat Position Accuracy | ±0.01mm |

| Printing Accuracy | ±0.025mm |

| Printing Speed / Cycle Time | <8s (Exclude Printing & Cleaning) |

| Product Changeover Time | <5 Minutes |

| Screen Stencil Size (Min~Max) | 470×340mm – 737×737mm |

| Screen Stencil Thickness | 20mm ~ 40mm |

| PCB Size (Min~Max) / Thickness | 80×50mm – 400×340mm / 0.4~15mm |

| PCB Warpage Ratio | <1% (Based on diagonal length) |

| PCB Bottom Clearance | 15mm (Standard), 25mm (Optional) |

| Edge of Board Size | 3mm |

| Conveyor Height | 900 ± 40mm |

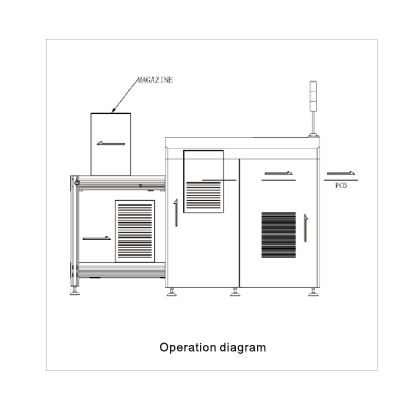

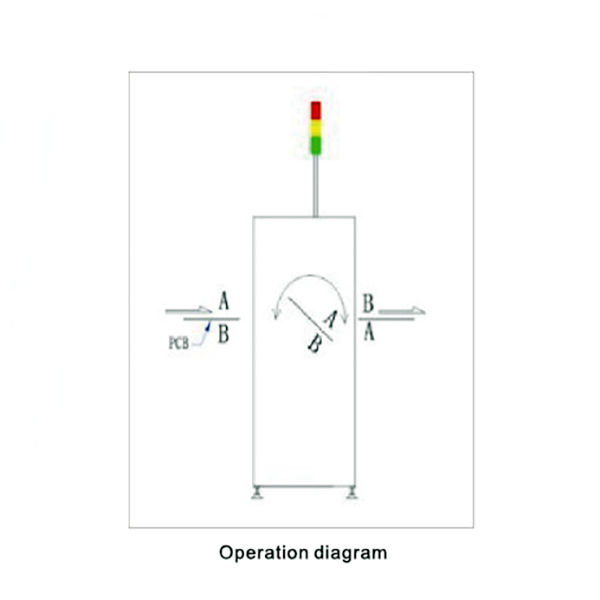

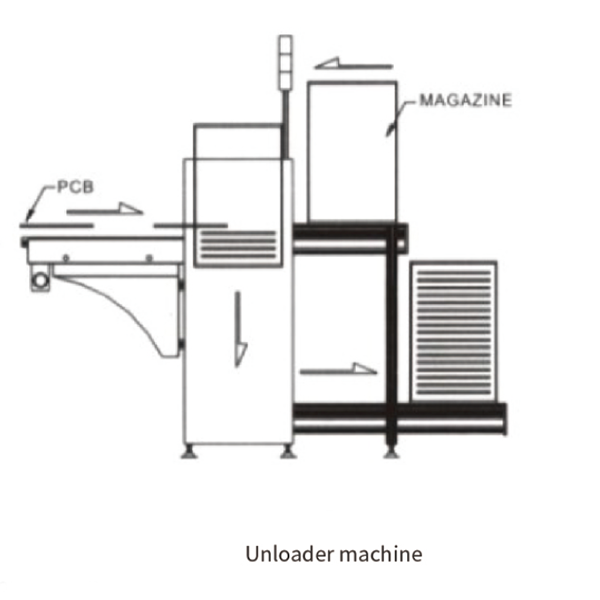

| Conveyor Direction | Left-Right / Right-Left / Left-Left / Right-Right |

| Conveyor Speed | 100 – 1500mm/s (Programmable) |

| Board Positioning Support | Magnetic pin / Side block / Flexible auto pin (optional) |

| Clamping System | Elastic side clamping / Vacuum nozzle / Z-direction adjustable table |

| Print Head | Two independent motorized print heads |

| Squeegee Speed | 6 – 300mm/s |

| Squeegee Pressure | 0 – 10kg (Software control, closed-loop feedback, visible pressure) |

| Squeegee Angle | 60° (Standard), 55°, 45° |

| Squeegee Type | Steel (standard), rubber, or customized types |

| Stencil Separation Speed | 0.1 – 20mm/s (Programmable) |

| Cleaning Method | Dry / Wet / Vacuum (Programmable combination) |

| Table Adjustment Range | X: ±3mm; Y: ±7mm; θ: ±2° |

| Fiducial Point Type | Geometry shape, bonding pad, stencil hole |

| Camera System | Single digital camera for upward/downward vision system |

| Air Pressure | 4 – 6 Kg/cm² |

| Air Consumption | Approx. 0.07 m³/min |

| Control Method | PC Control |

| Power Supply | AC 220V ±10%, 50/60Hz, 1Φ, 1.5KW |

| Machine Dimensions / Weight | Depends on exact model |

| Operating Temperature | -20°C ~ +45°C |

| Operating Humidity | 30% – 60% |