Features

-

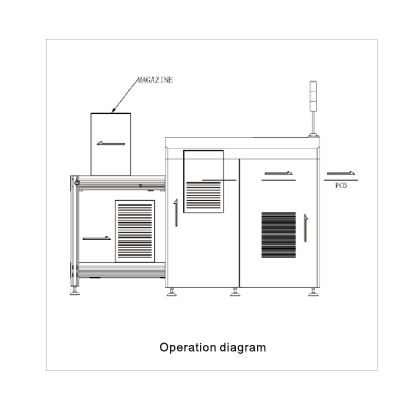

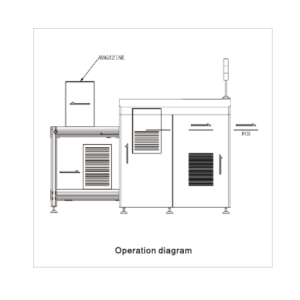

High-Strength Aluminum Alloy Structure: Special aluminum alloy frame provides excellent durability and allows users to clearly observe the magazine operation status.

-

Stable Integral Lifting Platform: Integrated casting lifting platform ensures smooth and stable PCB loading.

-

Advanced Electrical & Program Design: Multifunctional circuits and reliable programs guarantee stable operation and smooth PCB feeding.

-

Flexible Pitch Selection: Four pitch options available for adjustable PCB step distance during magazine feeding.

-

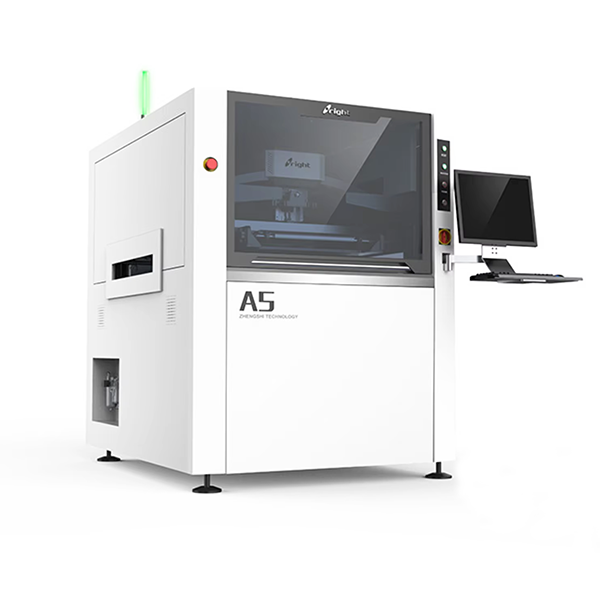

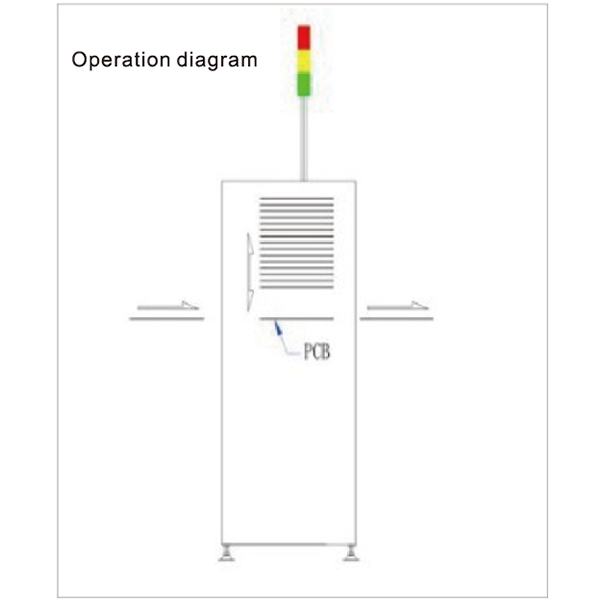

Intuitive Human-Machine Interface: 7-inch color touch screen with LED tricolor indicator for clear operation status.

-

Universal Suction Nozzle Positioning: Adjustable suction positions adapt to different PCB sizes and characteristics.

-

Efficient Board Handling: Lifting suction plate and adjustable push plate speed with three-point positioning and pneumatic clamping to protect PCBs.

-

Process Loss Reduction: Push plate protection system prevents PCB damage and minimizes production loss.

-

Seamless Integration: Standard SMEMA interface ensures compatibility with other SMT automation equipment.

Technical parameters

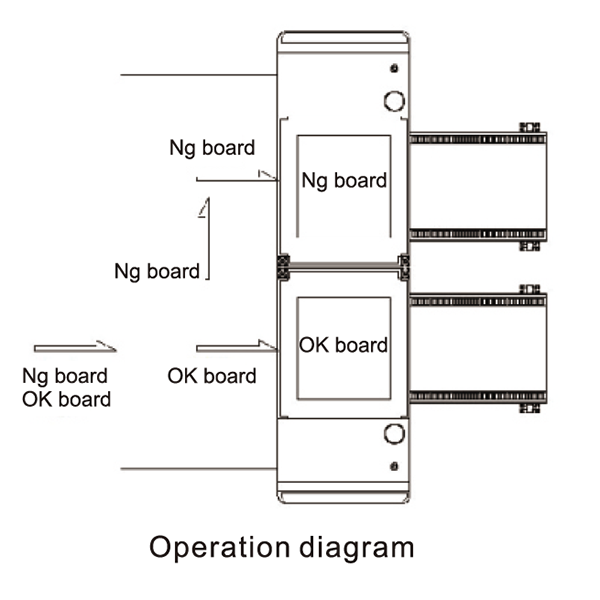

| Description | This unit is used for the automatic loading operation of double-sided boards and transceiver boards |

| No of magazine | Upper Conveyor: 1 magazine; Lower Conveyor: 2 magazines |

| Indexing pitch | 10, 20, 30, 40 mm or specify |

| Maximum PCBs capacity | 400 pcs (0.6 mm thick PCB) |

| Cycle time | Approx. 12 seconds or specify |

| Power supply | AC110V / 220V |

| Power | Max 300W |

| Air pressure | 4–6 bar, 30 L/min max |

| Transport height | 900 ± 20 mm (or customized) |

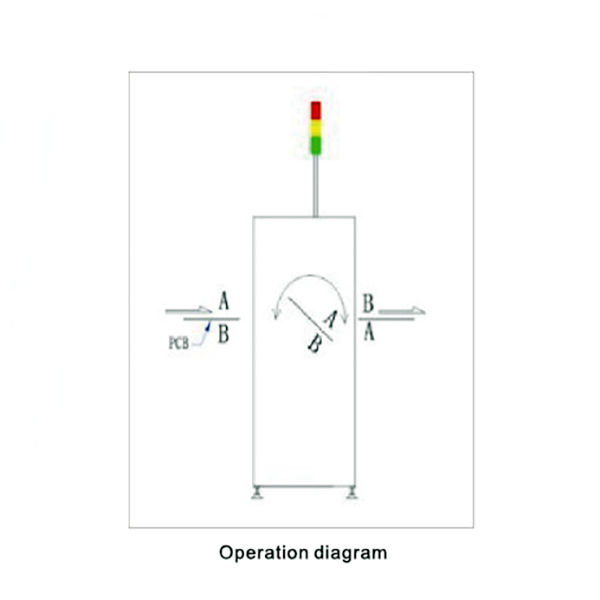

| Transport direction | From left to right or right to left |

Specifications

| Model | Dimension (L*W*H MM) | PCB size (MM) | Rack size (L*W*H MM) | Weight (KG) |

| VL-M-TN | 1800*865*1250 | 50*80-330*250 | 355*320*563 | 200 |

| VL-L-TN | 2220*945*1250 | 50*80-445*330 | 460*400*563 | 240 |

| VL-LL-TN | 2450*1110*1250 | 50*80-530*390 | 535*460*563 | 280 |

| VL-XL-TN | 2450*1250*1250 | 50*80-530*460 | 535*530*563 | 320 |